Specialized Actuators

Contact UsSpecialized Actuators for Aviation Applications

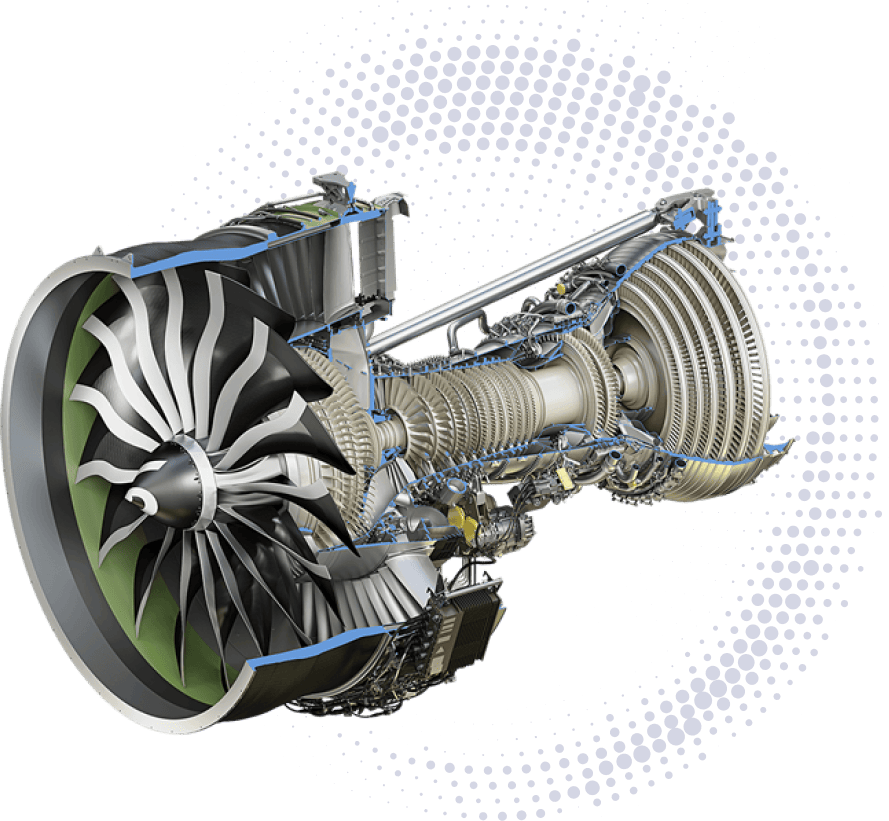

Aviation demands actuator solutions that go far beyond standard industrial capabilities. Specialized actuators represent custom-engineered components designed to meet unique aerospace requirements that off-the-shelf products simply cannot address. These precision devices enable aircraft systems to function reliably in conditions that would destroy conventional actuators.

From extreme-altitude operations to rapid temperature cycling, specialty actuators must perform flawlessly when lives depend on them. They convert electrical energy into controlled mechanical movement while withstanding harsh environments that include intense vibration, electromagnetic interference, and corrosive atmospheric conditions.

DK Turbines specializes in sourcing these critical components for aviation professionals who need actuators engineered for exceptional performance, reliability, and longevity in demanding aerospace applications.

What is a Specialized Actuator?

Specialty actuators fundamentally differ from standard industrial components due to custom engineering and rigorous aviation certification. Unlike industrial actuators for ground use, aerospace demands specialized designs for unique challenges.

These actuators translate control signals from aircraft systems into precise mechanical action, converting electrical energy into movement with exact timing and positioning, often within thousandths of an inch. Performance deviations risk compromising safety or operational capability.

Specialized actuators incorporate advanced materials, redundant systems, and fail-safe mechanisms lacking in standard components. They meet stringent aviation certification requirements via extensive testing across the entire operational envelope.

The linear motion must remain consistent through millions of cycles, whether extending landing gear or adjusting flight surfaces, without the wear acceptable in non-aviation use. Precision manufacturing and advanced material science ensure this longevity.

The Demanding Environments Specialized Actuators Must Survive

Aircraft actuators face extreme operational challenges, including massive temperature swings (from over 120°F to below -65°F), requiring flawless function where standard actuators would fail. They must generate immense force with minimal size and weight, as seen in components like landing gear actuators.

Additionally, aviation demands include surviving severe vibration and shock loads that far exceed industrial norms, necessitating advanced damping and reinforced construction.

Finally, these specialized components must maintain integrity against significant pressure differentials on pressurized aircraft and resist corrosion, particularly in harsh coastal environments.

Types of Specialty Actuators in Modern Aircraft

Modern aircraft depend on various specialized actuator configurations, each engineered for specific operational requirements:

- Electric ActuatorsOffer precise control through electronic control signal processing, enabling sophisticated positioning and force management. Modern fly-by-wire aircraft rely heavily on electric actuators for primary flight control systems, where their reliability and controllability prove essential.

- Linear Motion ActuatorsThese specialized linear actuators facilitate tasks like thrust reverser and cargo door operation. Their design ensures precise, forceful, fail-safe positioning, meeting emergency and aerodynamic load requirements for safe aviation use.

- High-Torque Rotary ActuatorsThese components provide substantial rotational force for power systems like valve actuators and accessory drives, while meeting the strict environmental and reliability standards of aviation.

- Combination ActuatorsProduce both linear and rotary motion through integrated mechanisms. These sophisticated specialty actuators simplify installation while providing multiple movement axes from a single component.

- Emergency Backup Actuator SystemsDesigned to operate independently when primary systems fail, representing a specialized category essential for aviation safety redundancy requirements.

Trusted Specialty Actuator Manufacturers We Work With

DK Turbines works with these leading aerospace manufacturers:

- General Electric

- Honeywell

- Cessna Caravan

- Bombardier Challenger

- Bombardier CRJ

- Dassault Falcon

- Hawker

Finding the Right Component Through Our Search Platform

Our comprehensive parts search platform gives maintenance professionals immediate access to specialized actuator specifications and availability information. The system contains detailed technical data for thousands of specialty actuator variants, including custom-engineered components for legacy aircraft platforms.

Search by part number or description to view real-time inventory status and pricing. As a leading procurement services provider, DK Turbines extends beyond our extensive stock—when specialized actuators aren’t immediately available, our team sources them directly from our network of trusted suppliers, ensuring you receive the exact component your aircraft requires.

Aircraft Platforms Requiring Specialized Actuator Solutions

DK Turbines supplies specialized actuators for a wide range of aircraft.

For Business Aviation (Learjet, Falcon, Citation, Challenger, Hawker), our custom components support cabin comfort and unique operational equipment.

For Regional Aircraft (Beechcraft 1900, Bombardier CRJ, Caravan), our inventory ensures reliable daily operations, from engine controls to environmental management.

For Legacy Aircraft, our extensive supplier network helps locate discontinued specialized actuators when standard channels fail.

For Modern Fly-by-Wire Systems, we provide sophisticated specialized actuators with the exact specifications and complete traceability documentation required.

The DK Turbines Difference in Specialty Component Sourcing

Aviation professionals globally choose DK Turbines for specialized actuator procurement.

With four decades in corporate aviation since 1983, we offer deep industry knowledge and supplier networks to solve difficult sourcing problems like obsolete or hard-to-find components. Our experienced team ensures technical compatibility and airworthiness compliance.

Every actuator includes quality verification and complete traceability documentation, guaranteeing compliance and protecting against counterfeit parts. We offer competitive pricing through efficient procurement and established relationships, delivering cost-effective solutions without compromising safety.

DK Turbines’ combination of technical expertise, comprehensive networks, and customer commitment distinguishes us in specialized actuator procurement across corporate and commercial aviation.