Rotary Actuators for Aircraft Systems

Contact UsRotary Actuators for Aircraft Systems

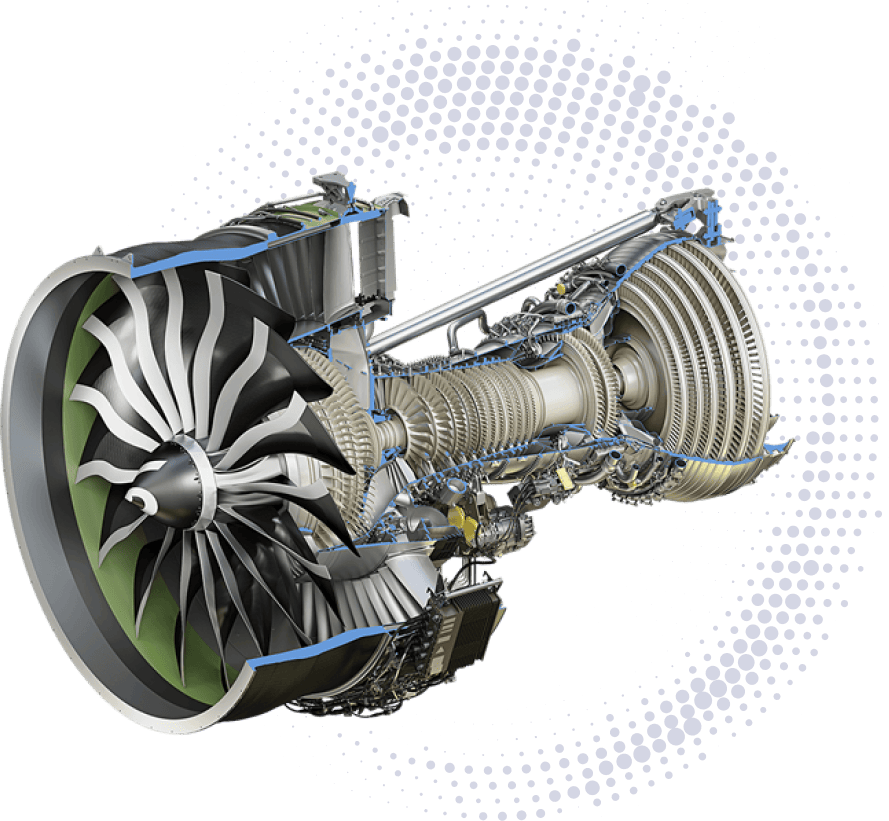

Rotary actuators are essential for modern aviation, providing the precise rotational motion required by aircraft valve systems, flight controls, and other critical accessories. By converting hydraulic, pneumatic, or electrical energy into controlled rotation, these specialized components enable crucial functions on aviation platforms, ranging from fuel valve positioning to the deployment of thrust reversers.

Rotary actuators create angular displacement, or rotational movement, in contrast to linear motion devices that move in a straight line. This turning force is essential for tasks like operating valves, rotating doors, and accurately positioning control surfaces. Precise timing and torque control are crucial for this rotational motion; any small error could negatively impact system performance or jeopardize aircraft safety.

DK Turbines specializes in sourcing quality rotary actuators that meet the demanding performance standards aviation professionals require for reliable aircraft operations.

What is a Rotary Actuator?

A mechanical device known as a rotary actuator generates controlled rotational movement based on command signals. Unlike linear motion actuators, which operate along a straight axis with a pushing or pulling action, rotary actuators are designed to turn or rotate components. This motion can be through a specific arc or continuous rotation, making them perfectly suited for tasks like valve operation and other comparable functions.

These actuators generate high torque within remarkably compact packages, a critical requirement in aircraft where installation space comes at a premium.

Different types of rotary actuators serve aviation needs based on specific performance requirements:

- Vane actuator designs use pressurized fluid acting on internal vanes to produce rotation, offering excellent torque-to-weight ratios for hydraulic systems.

- Rack-and-pinion rotary actuators convert linear motion into rotational motion through geared mechanisms, providing precise angular positioning.

- Electric rotary actuators deliver controllable rotation through motor drives, enabling sophisticated position feedback and electronic integration.

Each type addresses specific operational requirements while meeting stringent aviation certification standards that far exceed industrial applications.

Where Aircraft Depend on Rotational Motion Control

Valve actuation represents the most common application for rotary actuators throughout aircraft systems. Fuel control valves, hydraulic system isolation valves, and engine bleed air valves all require precise rotational positioning to regulate flow. These rotary actuators must open and close reliably across thousands of operational cycles while maintaining exact positioning under varying pressure loads.

Flight control systems utilize rotary actuators for trim tab positioning and certain secondary control surfaces where rotational motion proves more efficient than linear actuation. The high torque capability of aviation-grade rotary actuators overcomes aerodynamic forces while maintaining precise angular control throughout the flight envelope.

Engine systems employ rotary actuators for thrust reverser deployment, which redirect engine exhaust to provide braking action during landing. Landing gear door sequences often incorporate rotary actuators to swing doors through their travel arc, where rotational motion naturally matches the door’s pivoting movement.

Leading Rotary Actuator Manufacturers in Our Inventory

DK Turbines maintains a comprehensive inventory from these trusted aerospace manufacturers:

- General Electric

- Honeywell

- Cessna Caravan

- Bombardier Challenger

- Bombardier CRJ

- Dassault Falcon

- Hawker

Utilize Our Parts Search For Streamlined Part Finding

Our advanced parts search platform provides immediate access to rotary actuator technical data and availability across thousands of aviation components. Search by part number or component description to view real-time inventory status and pricing.

When specific rotary actuators aren’t immediately available from stock, our procurement team sources them through our established network of trusted suppliers, ensuring you receive the exact component your aircraft requires without delays.

Check out our Parts Search tool now!

Rotary Actuator Solutions Across Aviation Sectors

Different aircraft platforms demand different types of rotary actuators, and our inventory supports them all:

Corporate Aviation

DK Turbines specializes in the provision of rotary actuators for several business jet fleets. These essential components—which enable critical valve control and accessory operations—are supported across Learjet, Falcon, Citation, Challenger, and Hawker aircraft.

Regional Aircraft

Our inventory spans Beechcraft 1900, Bombardier CRJ, and Caravan platforms, providing the rotary motion control these workhorses require for daily flight operations.

Legacy Aircraft

Our extensive supplier relationships enable us to locate rotary actuators for vintage platforms when standard distribution channels cannot provide solutions.

Modern Fly-by-Wire Systems

We provide advanced rotary actuators with electronic position feedback and complete certification documentation that sophisticated aircraft systems require.

What Sets DK Turbines Apart for Rotary Actuator Procurement

Aviation professionals choose DK Turbines for rotary actuator sourcing because we understand the critical performance differences between aviation and industrial applications.

Over four decades in corporate aviation, we’ve built deep knowledge of the high torque requirements and environmental challenges that aircraft rotary actuators must overcome. Our quality assurance processes verify every rotary actuator against manufacturer specifications and airworthiness requirements, providing the complete traceability documentation that aviation regulations demand.

Additionally, our global supplier network enables us to source rotary actuators that other providers cannot locate, especially valuable for legacy aircraft and discontinued components.

Combined with competitive pricing and rapid worldwide delivery, we minimize aircraft downtime while ensuring the quality your operations require.