Aircraft Linear Actuators

Contact UsWhat is an Aircraft Actuator?

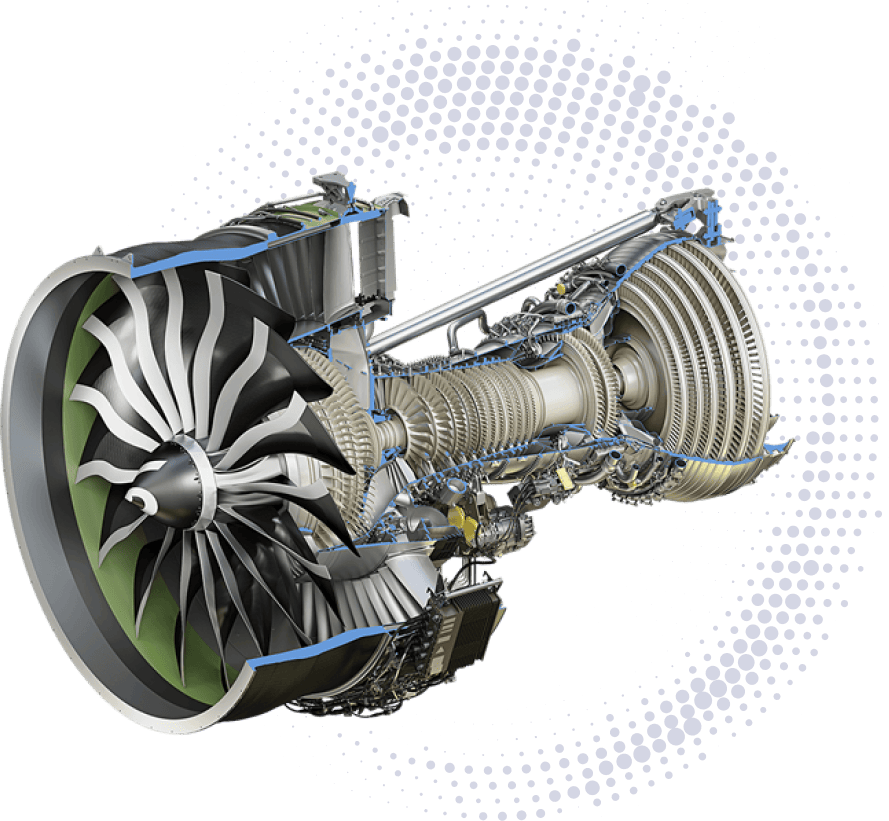

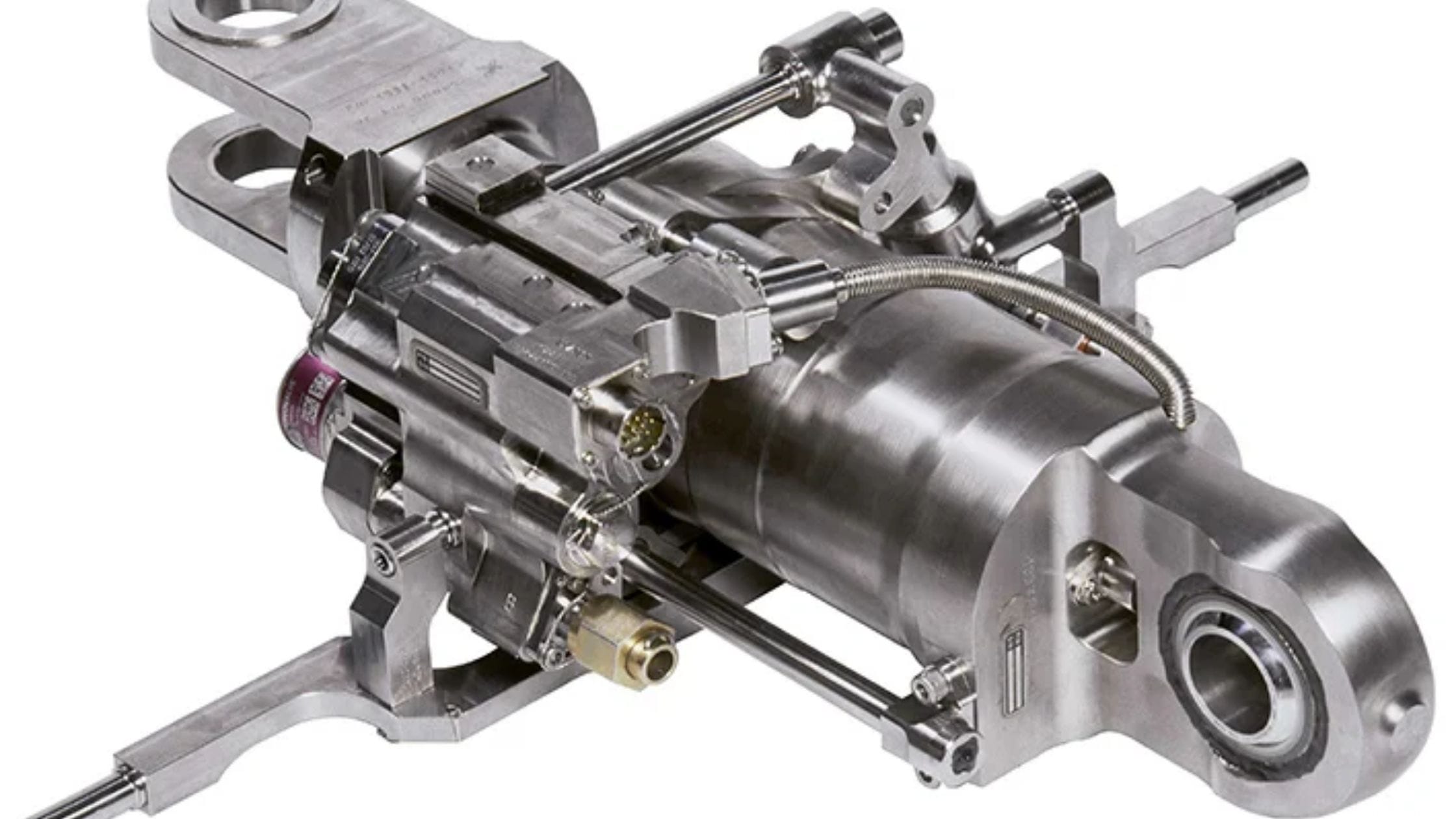

An aircraft actuator is a mechanical device that converts energy into controlled movement within aerospace systems. While actuators come in various configurations, linear actuators specifically produce straight-line motion rather than rotary motion, making them ideal for push-pull applications throughout the aircraft.

These precision devices receive commands from aircraft control systems and translate them into physical movement. Hydraulic linear actuators use pressurized fluid for powerful force generation, pneumatic actuators rely on compressed air for lighter-duty applications, and electric actuators offer precise control through motor-driven mechanisms.

Aerospace applications demand exceptional reliability standards that far exceed industrial actuator requirements. Aircraft linear actuators must function flawlessly across extreme altitude ranges, temperature fluctuations from -55°C to +170°C, and vibration conditions that would destroy conventional components. Every actuator undergoes rigorous testing and certification before entering service on commercial or military aircraft.

The lightweight construction of aerospace linear actuators represents another critical distinction. Engineers carefully balance strength requirements against weight penalties, since every pound affects aircraft performance and fuel efficiency. Advanced materials and innovative designs allow modern linear actuators to deliver substantial force while minimizing mass.

How Aircraft Linear Actuators Enable Safe Flight

Linear actuators power the flight control systems that pilots depend on for safe aircraft operation. These components adjust ailerons, elevators, and rudders with the precision necessary for smooth, controlled flight. Even minor deviations in actuator performance could compromise handling characteristics, making reliability absolutely paramount.

Landing gear systems rely heavily on linear actuators for extension and retraction cycles. These robust actuators must overcome significant aerodynamic forces while positioning gear components with exact timing and coordination. Redundant actuator systems ensure landing gear deployment even if primary units fail, providing essential safety margins during critical approach and landing phases.

Flaps and slats extend using linear actuators to modify wing geometry during takeoff and landing. These high-lift devices require synchronized movement across multiple actuator positions to maintain aerodynamic balance. The precision of modern linear actuators allows incremental flap settings that optimize performance for varying runway lengths and weather conditions.

Cargo doors, thrust reversers, and engine cowlings also depend on linear actuator operation. These systems demand reliable actuation in routine service while maintaining fail-safe characteristics. Commercial aviation regulations mandate specific actuator redundancy and monitoring capabilities to prevent in-flight malfunctions.

Linear Actuator Manufacturers We Carry

DK Turbines maintains a comprehensive inventory from these leading aerospace manufacturers:

- General Electric

- Honeywell

- Cessna Caravan

- Bombardier Challenger

- Bombardier CRJ

- Dassault Falcon

- Hawker

Advanced Parts Search Tool

Our streamlined parts search system provides maintenance professionals with immediate access to aircraft linear actuator specifications and availability. The database contains detailed technical information, compatibility data, and part numbers for thousands of aerospace actuator variants across commercial and corporate aviation platforms.

Users can search by part number or description, with real-time inventory status and immediate pricing for available components. As a leading procurement services provider, DK Turbines goes beyond our extensive stock inventory—if we don’t have the specific linear actuator you need on hand, our team will source it directly from our network of trusted suppliers. This comprehensive approach makes sure you get the right component when you need it, eliminating the hassle of contacting multiple vendors.

Applications Across Aircraft Platforms

DK Turbines supports linear actuator requirements across diverse aircraft categories, from light corporate jets to regional airliners. Our extensive inventory spans Learjet, Falcon, King Air, Citation, Challenger, Hawker, and Beechcraft 1900 platforms, providing you with comprehensive fleet support for maintenance operations.

Corporate aviation operators benefit from our deep knowledge of business jet actuator systems, including specialized components for cabin pressurization, environmental controls, and passenger convenience features. These aircraft often utilize electric linear actuators for quieter operation and reduced maintenance compared to hydraulic systems.

Regional aircraft and larger commercial platforms typically employ hydraulic linear actuators for primary flight controls and landing gear, where high force requirements exceed the capabilities of electric actuators. Our inventory includes actuators for these demanding applications, backed by complete traceability documentation and airworthiness certification.

Why Aviation Professionals Choose DK Turbines

For over four decades, DK Turbines has been the trusted source for critical linear actuator components and aircraft parts, making sure fleets remain operational. Since 1983, we have provided high-quality aerospace components, competitive prices, and exceptional customer service, prioritizing the urgency of aircraft maintenance.

We maintain extensive, immediate-access inventory for multiple platforms, covering TFE-731, TPE-331, CJ610/CF700, and PT6 engines. This comprehensive availability allows maintenance facilities to source complete actuator assemblies and components from a single supplier.

Our global shipping delivers rapid, worldwide parts delivery, minimizing costly aircraft downtime. Aviation professionals choose DK Turbines for deep industry knowledge, competitive pricing, and unwavering customer commitment, supported by technical guidance from our experienced sales team.