When it comes to aircraft maintenance, few procedures are as critical—yet often overlooked—as the proper aircraft brake bleeding procedure. Aviation professionals understand that this process isn’t just about following a checklist. It’s about ensuring the safety of everyone who relies on aircraft to stop when needed.

The brake system in any aircraft operates as a closed system, much like car brakes, but with significantly higher stakes. When air bubbles infiltrate hydraulic fluid lines, the result isn’t just a soft pedal—it’s a compromise to the entire braking capability of the aircraft. That’s why mastering the bleeding brakes procedure is essential for every aviation professional.

Understanding Aircraft Brake Systems

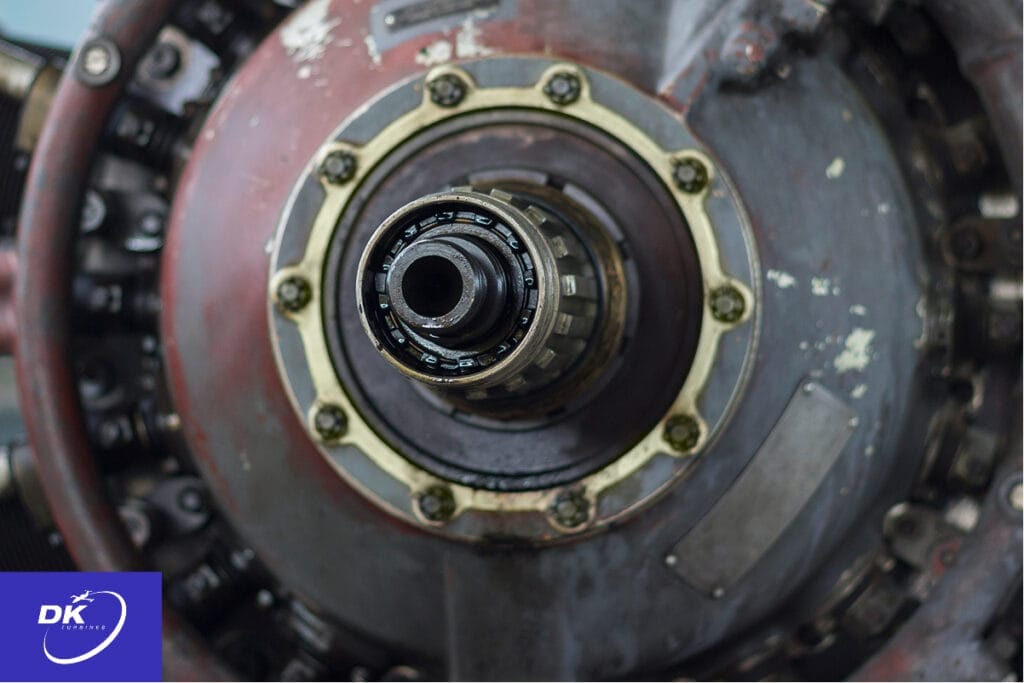

Before diving into the actual bleeding procedure, understanding the system components is crucial. A typical aircraft brake system consists of several key elements: the master cylinder, brake reservoir, brake lines, brake caliper, and the all-important bleeder valve. The master cylinder serves as the heart of the system, converting mechanical force from the brake pedal into hydraulic pressure that travels through brake fluid to actuate the brake cylinders.

The brake fluid itself is typically a specialized hydraulic fluid designed to withstand the extreme temperatures and pressures found in aviation applications. Unlike the brake pads found on ground vehicles, aircraft brakes often use different materials and configurations, but the fundamental hydraulic principles remain the same.

Trapped air represents the biggest threat to brake system integrity. Air compresses under pressure while fluid doesn’t, which means even small air bubbles can dramatically reduce brake pressure and effectiveness. This is why the aircraft brake bleeding procedure is so crucial—it’s all about removing every last bit of air from the system.

When to Perform Brake Bleeding

Recognizing when aircraft need brake bleeding is critical for safety. Signs include a soft pedal, inconsistent brake pressure, or brake pedal travel that extends further than usual before engaging. These symptoms typically indicate air in the system. After maintenance work on brake lines or replacing components like the brake bleeder valve, bleeding becomes necessary to restore proper fluid flow.

Many troubleshooting attempts for braking issues could be resolved with a simple bleeding procedure. The key is understanding that any time the closed system is opened—whether for repairs, component replacement, or routine inspection—air can enter the system.

It’s also important to note that all aircraft maintenance procedures, including brake bleeding, must be performed in accordance with FAA regulations such as 14 CFR Part 43, which outlines acceptable practices for maintenance, preventive maintenance, and alterations.

The Step-by-Step Aircraft Brake Bleeding Procedure

The aircraft brake bleeding procedure requires patience, proper tools, and meticulous attention to detail. Essential equipment includes a pressure pot or hand pump, clear hose or silicone tubing, appropriate brake fluid, and various wrenches depending on the aircraft’s specific fittings.

Begin by locating the brake reservoir and checking the fluid level. Remove the master cylinder cap and ensure adequate new fluid is available—old fluid will be replaced throughout the process. The strategy involves working from the highest point in the system down to the lowest, as air rises naturally through the hydraulic fluid.

Connect clear tubing to the brake bleeder screw, typically found on the brake caliper. This bleed hose should run into a container to catch the exiting fluid. When using a pressure pot, connect it to the brake reservoir according to manufacturer’s specifications. Some mechanics prefer using a hand pump system, which can be equally effective with proper technique.

Bleeding Techniques and Best Practices

- Pressure Bleeding Method: Apply consistent pressure through the pressure pot while opening the bleeder valve. Watch for clear fluid flowing through the clear tube, indicating that old fluid and air bubbles are being expelled. Close the bleed valve before releasing pressure to prevent air from being drawn back into the system.

- Manual Bleeding Method: Have an assistant pump the brake pedal while operating the needle valve or bleed screw. This method requires good communication and timing to ensure the valve is closed before the pedal is released, preventing air from entering through the caliper nipple.

Throughout either process, monitor the brake reservoir constantly. Never allow it to run dry, as this will introduce more air into the system and require starting over. Keep adding new fluid as needed, and always use manufacturer-specified hydraulic fluid—mixing different types can cause serious problems with seals and O-rings.

The flexible hose connecting to the bleeder screw should remain submerged in fluid to create one-way flow. Watch carefully for air bubbles in the clear line—when consistent, bubble-free fluid flows, progress is being made. However, don’t assume completion after the first clear flow. Air can hide in various system parts, requiring multiple cycles to fully purge.

Special Considerations for Different Aircraft Types

Different aircraft present unique challenges during brake bleeding. Cleveland brakes, common on many general aviation aircraft, have specific procedures that differ from those of other manufacturers. Race cars and high-performance aircraft often use more complex systems that may require specialized tools or techniques.

Some aircraft have parking brake systems that must be considered during the bleeding process. These systems can trap air in additional lines and cylinders, requiring separate attention. Always consult the aircraft’s maintenance manual for specific procedures, as what works on one aircraft may not be appropriate for another.

Harbor Freight and other tool suppliers offer various bleeding equipment, but investing in quality tools designed for aviation use is crucial. Many of these tools are not rated for aviation use and may not meet FAA-PMA standards or military specifications. For safety and reliability, use equipment specifically designed and approved for aircraft maintenance tasks. The higher pressures and safety requirements in aviation demand equipment that meets appropriate standards.

System Components and Maintenance Points

The brake system’s effectiveness depends on several critical components working in harmony. The master cylinder must maintain proper sealing to prevent air infiltration, while brake lines require regular inspection for wear or damage. The brake bleeder valve itself needs periodic maintenance to ensure proper sealing when closed and adequate flow when opened.

Brake pressure consistency throughout the system depends on eliminating all the air that may have entered during maintenance or through normal system operation. The wheel cylinder, whether it’s a traditional design or integrated into a more modern brake caliper configuration, must receive clean, air-free hydraulic fluid to function properly.

Regular inspection of the bleed screw and surrounding fittings helps prevent issues before they compromise brake performance. A clear tube during bleeding operations allows visual confirmation that air bubbles are being expelled and that clean fluid is flowing through the system.

Finishing the Job Right

Once consistent, clear fluid flow with no air bubbles is achieved, it’s time to complete the procedure properly. Close the bleed valve securely, but avoid overtightening—damaged threads or valve components can create future problems. Remove bleeding equipment and check all connections for leaks.

Top off the brake reservoir with new fluid to the proper level and replace the master cylinder cap. Test the brake pedal—it should feel firm and consistent. If a soft pedal persists after the bleeding procedure, additional trapped air may remain, or other brake system issues may require investigation.

The aircraft brake bleeding procedure might seem straightforward, but it requires attention to detail and respect for the critical safety function these systems serve. Take adequate time, follow proper procedures, and never rush this important maintenance task. When it comes to aircraft brakes, there’s no room for compromise—safety depends on getting it right every time.